Location: Mount Claremont, Western Australia

One of WA’s largest mental health facilities, engaged a renowned engineering firm to investigate the problems they were facing with their onsite sewer pump station.

The investigation revealed that two of their grinder pumps were not properly handling foreign objects in the waste water stream. This was causing pump failures due to objects becoming lodged in the pump, resulting in broken pump blades.

The engineering firm spoke to the facility manager who informed them that foreign objects including syringes, small empty alcohol bottles, small quantities of clothing and the odd bed sheet have been found in the pump. These objects were blocking the pump impellers rendering them ineffective.

When the system was designed and installed, it incorporated a separate primary screen pit. The screen pit is a large metal screen installed that removes the larger foreign objects that would impact the pumps. However, due to OH&S issues during regular cleaning and maintenance, the screen had been removed. Without its placement, foreign objects were able to enter the pump pit.

Additionally, the pumps were dealing with the loads and volumes just not the foreign objects. It was estimated that the old system could produce as much as 180,000L a day. But a more realistic volume of 83,000L would be expected.

They recommended a solution was an inline macerator and a bypass with the concrete structure remaining the same size to keep costs down.

The facility had approximately 1,053 fixtures, including toilets, basins, sinks, urinals, washing machines and showers. When all fixtures are used together at one time, they produce approximately 17,948 litres of waste. The assumption was made that only 50 percent of fixtures were used at one time. This brought the peak flow rate down to approximately 8,890 litres per hour.

The source of the debris was typically patients who were prone to throwing and flushing items down the toilets. This debris was causing sewerage pumps to block.

Allied Pumps was invited to customise the system to keep costs at a minimum, accommodating channel macerator and a bypass within the existing pit. Our biggest challenge was retrofitting a system for the existing primary screen pit constructed of reinforced concrete. The existing screen was 1025mm D x 1200mm W x 1300mm L.

There was also the need to combat OH&S servicing issues currently experienced with regular servicing and maintenance. Accommodating the 230mm pipe to handle sewer flows up to 180kL/day on continuous duty presented another challenge. For optimal operation of the hospital, the station was 100 percent essential.

The hydraulic services consultant had viewed a possible solution of:

We investigated in-line and a bypass macerating system to deal with the raw sewage from the hospital. The in-line system pipe feeds directly into the grinder, which processes the debris and comes straight back out again. The disadvantages of this system are that it can only take a certain feed and operates on a dry tank.

Original dimensions of the macerator and bypass were too big for the pit. To fit in the bypass system, we would’ve had to extend the pit. This would be too costly and was considered a last resort.

Hydraulic pressure required by the macerator at fill flow is approximately 100-150mm. Some back up is expected. The system is located away from all facilities so that will just back up in the pipe.

A bypass system works where peak flows can be bypassed into a wet tank and stored.

After numerous discussions with the site contractor, the most practical option was to install a channel grinder in the existing mechanical screening pit. We designed specialised guiderails from 316 stainless steel. They were built in-house to suit the existing concrete structure.

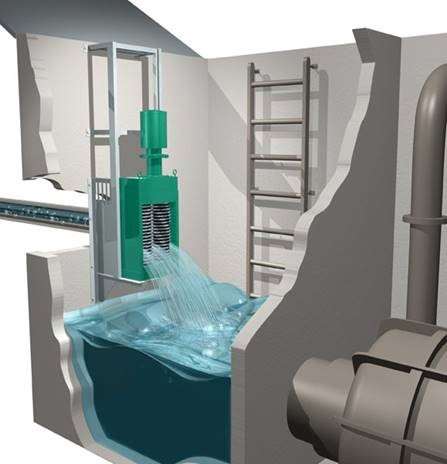

The macerating system was customised within the tight constraints of the existing structure. A buffer plate was used on either side of the channel grinder to push the flow into the grinder. The configuration of the channel type grinder allows overflow without manual intervention. The inline Muffin Monster macerator uses powerful grinders to grind up waste solids. It then converts the solids into a fine slurry that flows to the sewerage. The pit remains a wet well, and the channel grinder bolts directly to the concrete wall directly over the inflow pipe. Lifting points were connected and used for servicing crew to access the macerator above ground. This addressed any OH&S servicing and maintenance issues.

Many man hours were spent visiting the site with the engineer and the client. Extensive time was spent installing and commissioning. We also took much time in measuring and co-creating the system and guide rails in-house with our team of welders. Numerous adjustments were required to get this to fit. The system was complemented by guide rails constructed in-house. The accessories were built from 316 stainless steel to resist corrosion.

Despite shipping time from the U.S. manufacturer and freight delays, we were able to meet the project deadline. Getting projects completed on time and accurately is always a top goal. The facility was very pleased. Peak flow no longer experiences blockages. The system has now been up and running for 24 months with no issues.

To discuss your waste water management needs, please contact us today

Contact us to learn about how we can help you with your pump needs.

CALL US NOW EMAIL US