If the number of cooking programs on the television is anything to go by, more people are spending a lot of time in the kitchen creating veritable masterpieces every night of the week. While this may or may not actually be true, the kitchen in almost every household will see food created and consumed many times a day. And what accompanies food creation and consumption is dishes and lots of them.

Regardless of whether you use a dishwasher or hand wash dishes, chances are going to be good that some fat oil and grease will run into drains and eventually sewers. Detergents, that claim to dissolve grease, simply move grease down the pipe and create a larger problem downstream.

As the detergent becomes diluted and the waste water begins to cool and mix with other debris in the waste stream it solidifies and can stick to the inside of the pipes. Over time these small pockets of fat balls become larger until such time they eventually block the pipes completely and need to be removed.

If we can prevent Fat, Oil & Grease (FOG) entering the wastewater stream while at the same time prevent other materials such as ear buds and “flushable” wet wipes from being flushed away, these “fatburgs” can be prevented.

Sounds simple, but it is hard to control outside of your own surroundings.

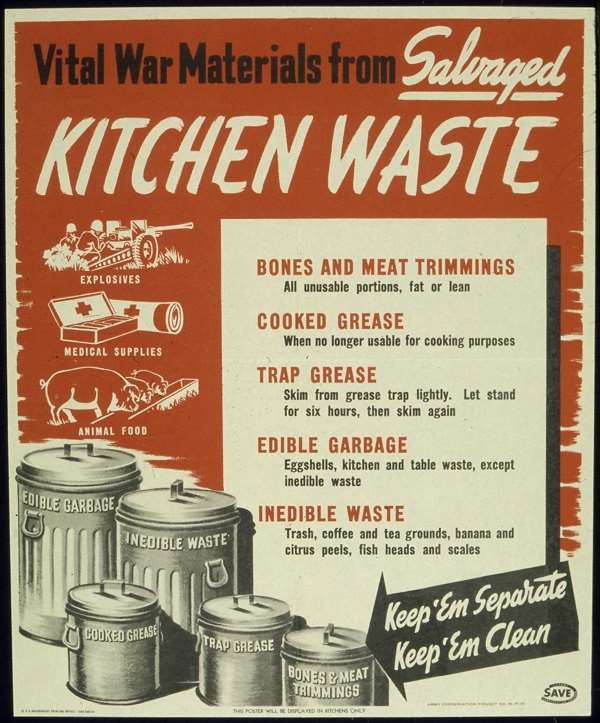

One of the biggest contributors to FOG in the waste water streams comes from restaurants and fast-food outlets who do not have adequate grease control measures in place. Grease filters / grease traps are not the most glamorous part of owning a successful food business, but it could be argued they are one of the most important. Without adequate measures to maintain and manage your grease trap as required by your local water authority, your restaurant will be unable to meet all the rules and regulations of health and safety – and it doesn’t take much to have patrons vote with their feet and head elsewhere to eat out.

The other big issue with waste water streams is what is washed down restroom drains and flushed down the toilets.

Unfortunately, we know of many instances where people have attempted to flush the unflushable and the inevitable breakdown is a result. The good news is that there is a range of inline macerators with wipes ready teeth. With 2-Dimensional cutting capabilities they control both the width and length of output, preventing material from forming long strips and reweaving in the waste stream.

Read more about how we solved this issue for a health care facility.

So what can be done?

There are a number of measures that can assist with FOG and debris in the waste water stream.

The patented ALLIED pumps Grease Muncher combines the conventional underflow grease arrestor design with a special Biofilter which dramatically reduces the grease content of the discharge through microbiological activity.

Allied Pumps also supply a range of inline macerators. The Muffin Monster Grinders are renowned for their WIPES READY technology preventing materials from forming long strips and reweaving in the waste stream by using 2-dimensional cutting capabilities to control both the width and length of output.

To discuss your waste water management needs, please contact us today.

Contact us to learn about how we can help you with your pump needs.

CALL US NOW EMAIL US