When considering water supply for high rise buildings, structural engineers will want to take into account the pros and cons of pressure up and pressure down water supply systems.

With a pressure up system, the system is typically divided into zones and a number of booster pumps provide the pressure which is necessary for optimum user comfort. A pressure down system involves a roof tank, a solution that was created as taller buildings were built, resulting in a requirement for more water for both domestic use and fire-fighting.

With a roof tank on a high rise building, water pressure and water supply for domestic use and fire-fighting is readily available, even when there is no electrical power. However, there are greater structural requirements for installing water storage tanks on a roof. The demand for space, the restrictions it will impose in terms of extending the height of a building, and its impact on the value of real estate must also be taken into account.

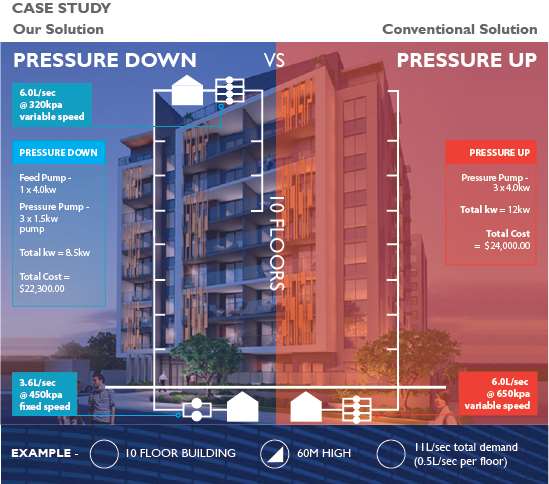

With many new buildings, there is a push to use a single basement tank and basement pumps pressuring to the top of the high rise or apartment block. With Motive Apartments in Perth, we designed a system to keep the rooftop tank full by installing a small pump in the basement. The pump effectively transfers water from the basement to the rooftop. The top floors of the block are served by smaller, variable speed pumps, and the lower levels are fed by gravity.

Since the system uses smaller pumps that run less often, the client has benefited from huge savings in terms of electricity costs, and the system can still supply water to residents in the event of a power outage.

System configurations for pressure up systems include: a single booster system; a zone divided system where a zone supplies 12 floors; a series-connected system with intermediate break tanks so that every zone is served by its own booster set; and a series-connected system.

When selecting the right system for your application, take the following into account:

Choose a supplier that can offer a turnkey package and who is willing to partner with you to achieve the exact configuration you need. This has to include technical support during and after installation, troubleshooting, and system sustainability.

To discuss your next pressurised water system project please contact Allied Pumps today

Contact us to learn about how we can help you with your pump needs.

CALL US NOW EMAIL US