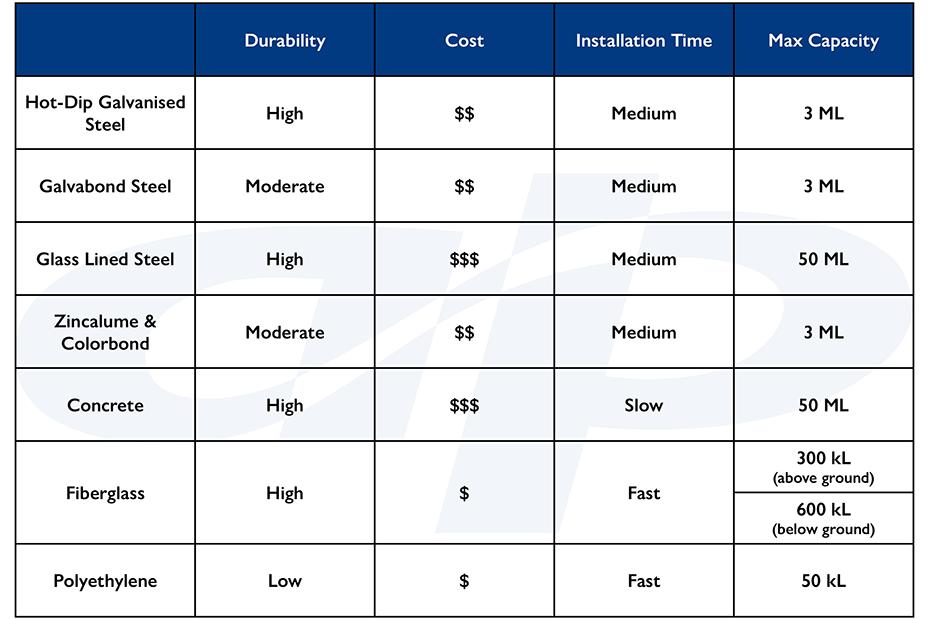

Water storage is a critical component of mining and industrial operations. This means understanding the strengths and limitations of each material is key to making an informed decision. In today’s article we will analyse the durability, cost, installation time, and capacity of the most common water tank materials.

Hot-dip galvanised steel tanks are strong, impact-resistant, and offer a long lifespan when properly maintained. Their zinc coating provides moderate corrosion resistance, though prolonged exposure to harsh environments can cause degradation over time. To extend their durability, a powder coating can be applied, enhancing their resistance to rust and environmental damage.

These tanks fall within the mid-range in terms of cost, being more affordable than glass lined steel but more expensive than poly or fiberglass alternatives. Installation is relatively straightforward, as modular panel systems allow for easy transport and on-site assembly. At Allied Pumps, we use a tank jacking system to improve safety and installation time.

Galvabond steel tanks offer similar durability to hot-dip galvanised steel but with a thinner zinc coating, making them slightly less resilient. Their corrosion resistance is moderate, making them suitable for less aggressive environments. However, applying a powder coating can significantly improve their longevity and resistance.

These tanks are more cost-effective than hot-dip galvanised steel but may not be ideal for large-capacity applications due to their thinner protective layer. Finally, installation is simple, and prefabricated options in conjunction with our tank jacking system allow for quick assembly.

Glass-lined steel tanks are among the most durable options, thanks to the fusion of glass and steel, which provides excellent mechanical strength. Their standout feature is their superior corrosion resistance—the glass coating effectively prevents rust, chemical damage, and microbial growth.

While these tanks are more expensive than galvanised options above, their longevity and low maintenance requirements make them a worthwhile investment. The modular design simplifies transport and assembly, but installation requires precision to avoid damaging the glass lining. Our tank jacking system is extremely reliable in ensuring no damage occurs during installation.

Zincalume steel offers excellent corrosion resistance, while Colorbond steel takes it a step further with a factory-applied coating that enhances longevity. These tanks fall within the mid-range of pricing, generally costing less than the galvanised and glass lined steel options. Finally, their modular design in conjunction with our tank jacking system allows for safe and fast installation times.

Concrete tanks are among the most durable options. Their corrosion resistance is excellent, as they are inherently resistant to rust, though they may require sealants to prevent water seepage. However, these advantages come at a high cost, with both material and installation expenses being significant. The installation process is labour-intensive, involving site preparation, formwork, curing time, and reinforcement, making it one of the most complex options.

Due to the curing process, installation can take weeks or even months, which may not be suitable for operations requiring a rapid deployment. Additionally, these services are often not available for remote sites.

Fiberglass tanks provide a strong yet lightweight alternative. They are highly resistant to corrosion, UV exposure, and cracking, making them ideal for aggressive chemicals and saline environments. Fiberglass is also more cost-effective than steel and provides a long-lasting solution with minimal maintenance.

Installation is relatively easy, as these tanks are prefabricated and can be transported and set up quickly. This makes fiberglass tanks among the fastest options to install. However, they do come with their limitations, most notably size.

Polyethylene tanks are the most cost-effective option, offering excellent impact resistance and flexibility. They are fully resistant to rust, chemicals, and most environmental conditions, though long-term exposure to UV rays can cause degradation.

These tanks are lightweight and easy to handle, with many being pre-moulded for quick installation. Their installation time is the shortest among all tank materials, but much like fiberglass tanks, they are limited by size.

Choosing the right water tank material is critical for mining and industrial applications. At Allied Pumps, we provide expert advice and tailored water storage solutions for your operations. Our choice of tank materials includes:

Additionally, we can design tank to be insulated, cyclone rated, and with protective finishes like powder coating. Combined with our tank jacking system, you can expect your tanks to be durable and installed in record time. Contact us today to discuss your project and find the best tank for your needs.

Contact us to learn about how we can help you with your pump needs.

CALL US NOW EMAIL US