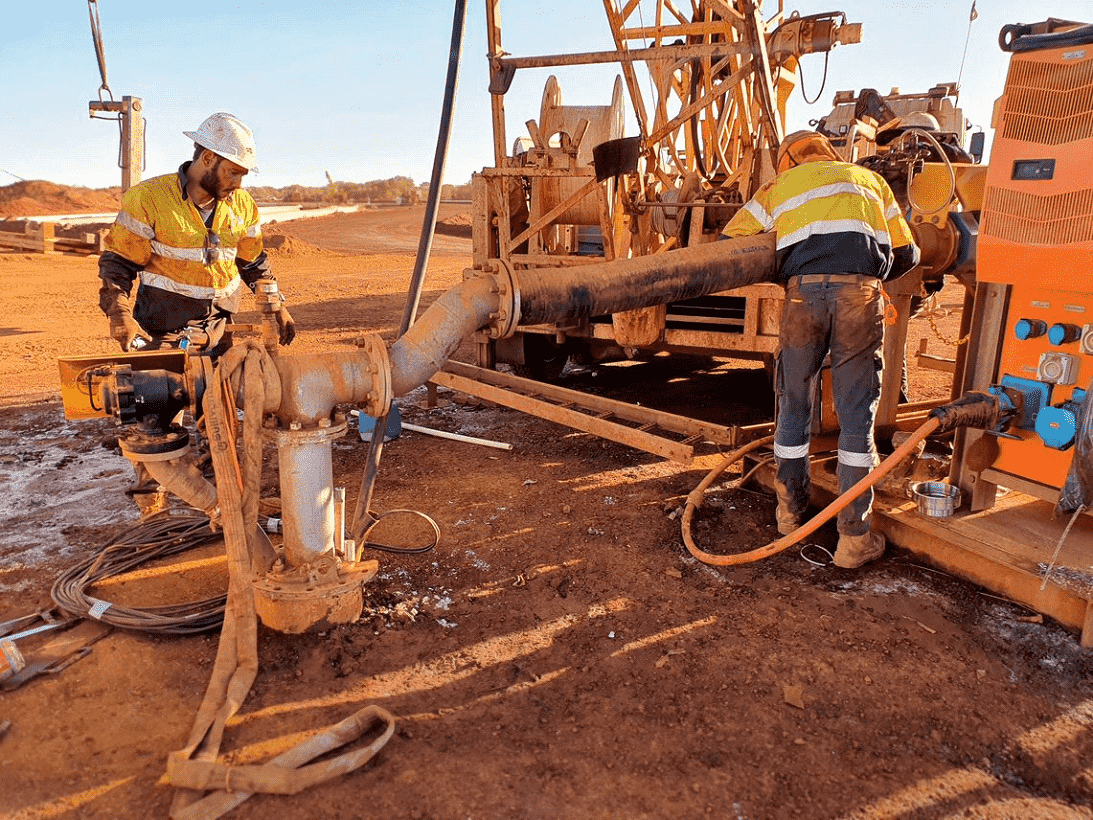

No industry continuously puts its pumps through harsh conditions like the mining industry. When you are under pressure to meet output targets, the last thing you want is for your mining pumps to fail- especially if it’s easily preventable.

Today we’ll be discussing four common faults you may experience as well as some ways to avoid them.

One of the most common and frequent causes of mine pumps failing is clogging. Over time, suspended solids clump together and cause the pump to clog.

The key to avoiding this issue lies in selecting a pump designed to meet your needs. No matter what mix of solids to liquids you have – there are pumps designed to handle it. By choosing the right pump, you can reduce or eliminate problems down the track.

Mine pumping deal with a range of punishing liquids and environments. From emulsified brine to phase drilling fluid – your pump will have to withstand some harsh materials.

The best way to minimise the effect of corrosion is to select a pump designed specifically for the task at hand and constructed using the highest quality materials. Selecting pumps constructed with appropriate metallurgy is the best way to increase their lifespan and reliability. Many construction materials, including super-duplex, stainless steel, and even some polymers, offer excellent protection and durability in particularly harsh environments. Although being more expensive, these pumps deliver solid performance even after years of contact with liquids that would damage a pump made from standard construction materials.

Another solution to prevent your pump from failing due to corrosion is to use anodes. Andoes are made of metal that has a lower ‘electrode potential’, such as magnesium, zinc or aluminium. The majority of the corrosion will occur on these softer materials and not the important elements within your pump. It is crucial to monitor anodes and replace them as they become worn out over time.

Sometimes corrosion is inevitable. In some applications – even the hardest metal will succumb to corrosion – but using anodes and choosing the right pump will certainly help.

Protecting your pump is essential to avoid damage from mine traffic or accidents. Location is key here; you want to place your pump in an area that is, as much as possible, away from heavier and larger equipment. Carefully choosing your pump location can mean the difference between getting on with the job and suddenly stopping everything for a costly pump replacement.

Overheating is something that can occur if the water levels in your pump are too low. Especially during prolonged operation, the pump might run dry and overheat, leading to damage or even complete failure.

Overheating can also be caused by the build-up of suspended solids in the cooling chamber. To prevent both of these issues, it’s important to make sure your system is running correctly. Carefully monitor water levels and make sure regular maintenance checks are performed.

For situations where monitoring is difficult, or just for peace of mind, consider installing a pump with appropriate protection. When these systems detect variables (temperatures, water levels or pressure) outside safe operating parameters, they automatically shut down to avoid damaging the equipment. While a pump that stops can be inconvenient, it’s a lot better than having to replace a pump that has been cooked.

For more information about mining water treatment systems or to learn more about any of our sewage and greywater treatment and storage options, call us on 1800 335 550 or email us at sales@alliedpumps.com.au.

Contact us to learn about how we can help you with your pump needs.

CALL US NOW EMAIL US